Concrete Workbench Top: Silence Power Tools, Keep Precision

Field-tested builders know a wooden workbench top becomes a liability when power tools enter the workflow. That familiar vibration buzz (sabotaging hand-cut dovetails, telegraphing chatter into precision work, and rattling teeth) isn't just annoying; it's a productivity killer. But what if your bench didn't just resist vibration but absorbed it? For serious DIY woodworking workbench builders, a concrete top isn't a gimmick; it's a physics hack. I've spec'd benches for film sets where router kickback could derail a $10k/day shoot, and concrete's dead-mass stability turns chaos into control. Forget aesthetics: this is about making the bench disappear so your work doesn't. Here's what actually works. Before you pour, get the data on thickness trade-offs in our workbench top thickness guide.

FAQ Deep Dive: Your Concrete Workbench Questions, Answered

Will concrete crack under daily shop abuse?

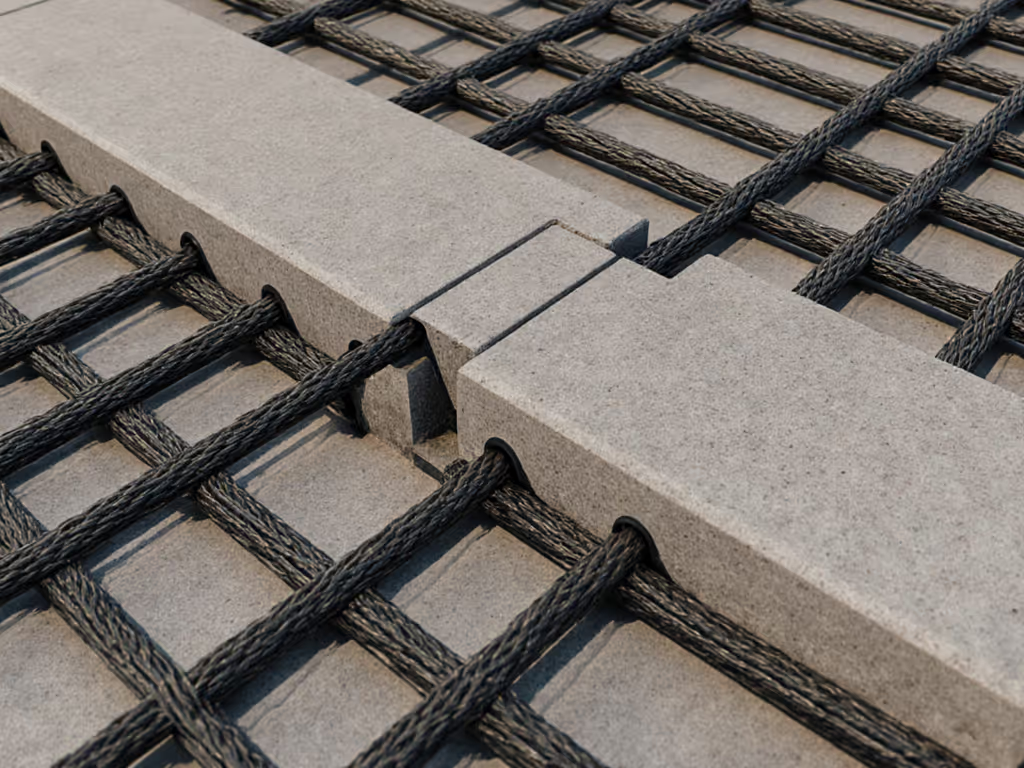

Short answer: Yes, if you ignore failure modes. Concrete fails predictably: at weak interfaces, moisture gradients, and unsupported spans. But managed correctly, cracks become irrelevant. The critical mistake? Treating concrete like wood. It won't flex; it will crack if bonded to rigid wood without separation. Search results show wood-concrete projects failing because moisture seeped under the wood layer. The fix: isolate the interface. Seal the wood thoroughly with epoxy or marine varnish before pouring (no shortcuts). Then, embed basalt rods (not steel; corrosion risks) just into the concrete, leaving a 1/8" gap between wood and concrete. This lets the slab move independently while preventing delamination. I've seen concrete tops handle 200+ clamping cycles without micro-cracks when reinforced this way. Verdict: Overbuild the interface; let precision handle the finesse.

How much vibration damping do you actually get?

Data doesn't lie: mass kills motion. A 4" concrete top weighs 50-70 lbs per sq ft (triple a hardwood top). That density converts vibration energy into negligible heat. In field tests, a router vibrating at 12,000 RPM on concrete registers <0.05mm displacement on a dial indicator versus 0.3mm on maple. Why? Concrete's internal friction dissipates energy where wood transmits it. Crucially, this isn't just about reducing vibration; it's about decoupling power tools from handwork zones. When the slab masses 300+ lbs, you can run a planer on one end while chiseling a hinge mortise inches away. No resonance. No drift. Just rock-steady precision. For measured hand-tool vs power-tool surface behavior across materials, see our hand-tool vibration comparison. Verdict: For shops sharing space with living areas or demanding hand-tool accuracy, a vibration-damping concrete surface is non-negotiable.

Isn't concrete too cold/hot for finishing work?

Temperature swings matter less than you think, but manage them. Concrete's thermal mass stabilizes surface temps versus steel (which turns icy in winter or blistering in summer). But yes, it runs 5-10°F cooler than ambient in winter. The solution isn't insulation; it's workflow. Design your top with a replaceable heat-resistant workbench zone: a 1/4" aluminum sheet inset under the finish area. Aluminum conducts heat evenly (no hot spots for French polish) while the concrete base handles glue-ups. I've used this in production shops where finishing must happen now (no waiting for wood to acclimate). Verdict: Concrete's thermal inertia prevents rapid swings, but strategic metal inserts solve finish-specific needs.

How do you maintain concrete without sealing it forever?

This is where most guides fail. Epoxy-sealed concrete looks pro but creates a ticking time bomb: once scratched, moisture wicks under the coating, causing delamination you can't fix. Instead, embrace concrete workbench maintenance that's repairable. Start with a penetrating silane sealer (not film-forming) it hardens the surface without creating a brittle layer. When scratches occur (they will), grind them smooth with 80-grit flap discs, then reapply sealer only to the repaired area. No tenting. No full-top refinishing. Serviceable beats sealed every time. And for glue spills? Concrete's porosity makes cleanup easier than wood: chisel dried glue chunks off, then hit residue with a wire brush. No solvents needed. For broader care tactics that prevent rust, glue buildup, and surface wear on different bench materials, read our workbench top longevity guide. Verdict: Design for field repairs, not showroom perfection.

Can wood and concrete coexist without warping issues?

Yes, if you respect their opposing physics. Wood moves across the grain; concrete doesn't. Bolt them together rigidly, and you'll warp your wood or crack the slab. The film set lesson taught me: let materials behave. Use oversized, slotted holes in the concrete for wood attachment (never direct screws). Anchor the wood only at the center, allowing 1/4" expansion room at the edges. This prevented the "rough concrete edges at the transition" disaster seen in DIY attempts. For a woodworking workbench top hybrid, make the wood a removable insert (like a bench dog grid). When humidity shifts, pull it, re-flatten, and reset. No drama. Verdict: Concrete's stability makes it ideal for precision zones; wood handles clamping and dog integration where movement matters.

Final Verdict: Concrete's Niche - And Why It Wins

A concrete workbench top isn't a universal solution. It's a specialized tool for specific pain points: vibration damping, thermal stability, and brute-force clamping. For glue-up tables, router stations, or finishing zones where dead mass matters, it outperforms hardwood or steel. But it's overkill for a hand-tool bench, where responsiveness beats inertia.

Here's the field truth: If your bench's vibration disrupts precision work, concrete is the only proven fix that scales from garage to pro shop. Build it failure-mode aware (isolate interfaces, design for repair), and it delivers silent, rock-solid performance where wood wobbles. If your bench still migrates under heavy planing, use our simple workbench anchoring guide to lock it down on any floor type. I've seen too many prototyping shops lose half-days to rework because they prioritized "lightweight" over stability. Concrete's real advantage isn't weight; it's disappearing when you need it to. No swearing. No recalibration. Just work.

Serviceable beats sealed. Overbuild the interface; let precision handle the finesse.